Thermoplastics offer a range of benefits that make them the material of choice for numerous industries. Lightweight yet incredibly strong, thermoplastics provide a high strength-to-weight ratio that enhances performance while reducing overall weight. Their inherent corrosion resistance and durability ensure longevity and reliability, even in the most demanding environments. Thermoplastics are also highly versatile, allowing for repeated melting and reshaping without losing their chemical properties. At Re:Build Oribi, we harness the advantages of thermoplastics to deliver innovative, high-performance composite solutions tailored to the specific needs of your application. Explore how our advanced thermoplastic composites can elevate your products and drive your success.

Thermoplastics, with their ability to be repeatedly reshaped and recycled, offer greater versatility and efficiency compared to thermosets, which become rigid and inflexible after curing. This adaptability makes thermoplastics a more practical choice for a wide range of modern applications, emphasizing sustainability and ease of use.

Thermoplastics are polymers that become pliable when heated and solidify upon cooling. This reversible process allows thermoplastics to be melted and reshaped multiple times without altering their chemical properties. Their versatility, recyclability, and ease of processing make thermoplastics ideal for a wide range of applications, including automotive parts, medical devices, consumer goods, and packaging.

Thermosets are polymers that, once cured through heat or chemical processes, form irreversible bonds. This curing process creates a rigid, inflexible structure that can withstand high temperatures and chemical exposure. Common applications for thermosets include electronic components, adhesives, and coatings where durability and heat resistance are crucial.

Thermoplastics and metallics each offer its own benefits depending on the application. While metallics provide exceptional strength and durability, thermoplastic composites stand out for their lightweight, versatile, and easily moldable properties.

Metallics are materials composed of metal elements that exhibit high strength, durability, and thermal conductivity. Metals are typically heavier than thermoplastics and require more complex processing techniques such as casting, forging, and machining. They are favored in applications where extreme strength, rigidity, and heat resistance are essential, such as in aerospace, construction, and heavy machinery.

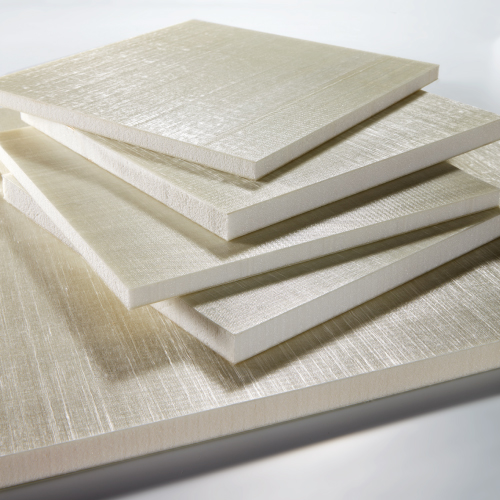

Thermoplastics are lightweight, versatile polymer composites that become pliable when heated and solidify upon cooling. This characteristic allows them to be melted and reshaped multiple times without losing their chemical integrity. Thermoplastics Composites are known for their high strength-to-weight ratio, corrosion resistance, and ease of processing. They are commonly used in applications such as automotive components, medical devices, consumer goods, and packaging.

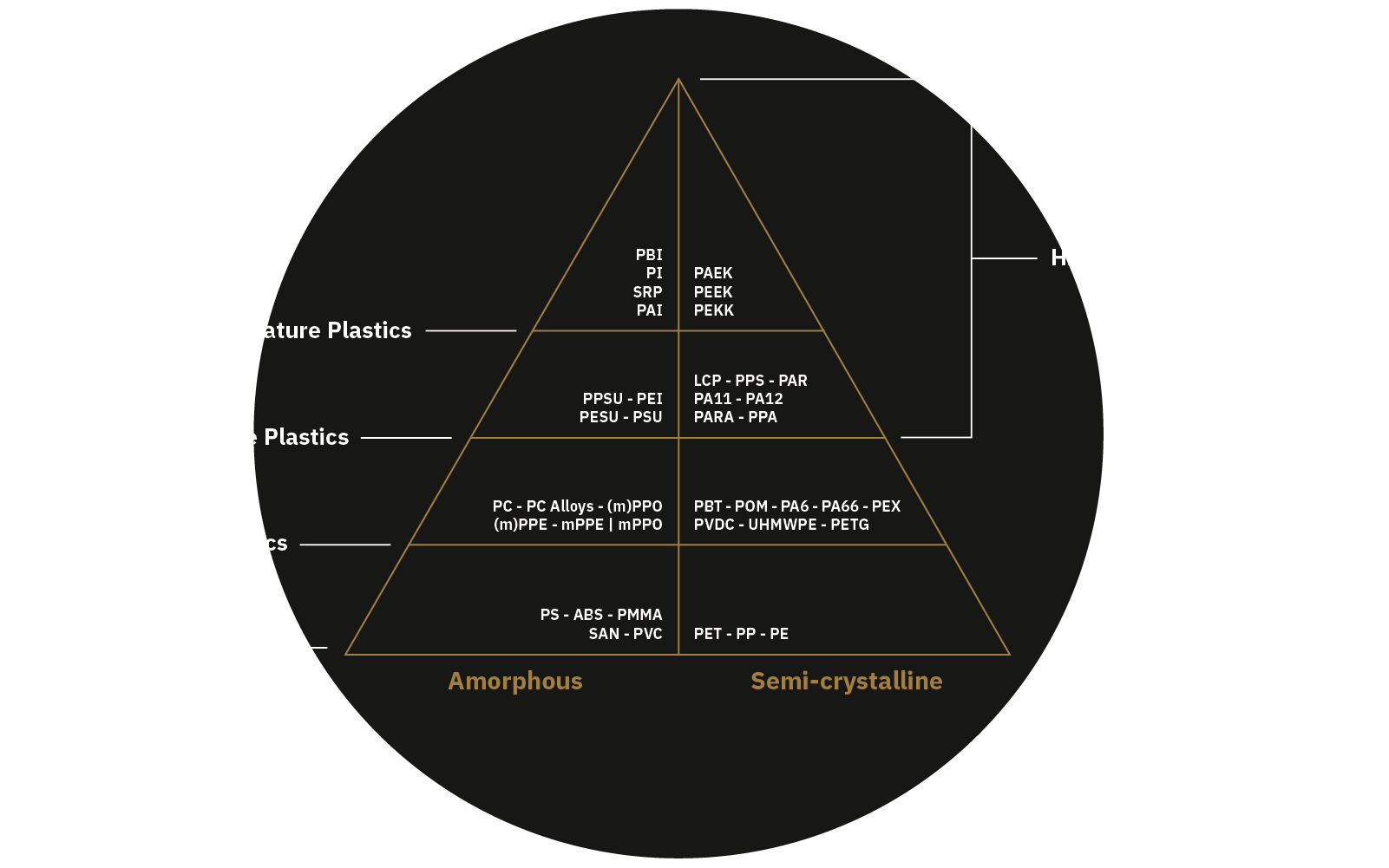

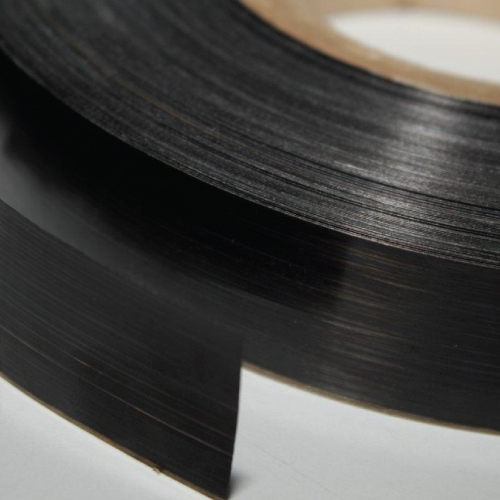

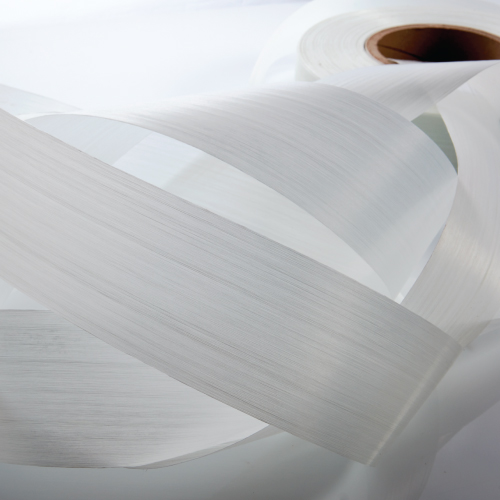

At Re:Build Oribi, we specialize in advanced thermoplastic composites, selecting from a wide range of engineered resins based on specific end-use requirements. Our process handles a variety of melt-processable polymers, from high-temperature PEEK and PEKK to low-temperature polyolefins like PP and PE, reinforced with carbon or glass fibers. These lightweight, corrosion-resistant solutions provide a cost-effective and sustainable alternative to traditional metallics, meeting the demanding performance needs of various industries.

Our advanced manufacturing process is designed to accommodate a wide range of melt-processable polymers, offering flexibility depending on your performance needs. From high-temperature polymers like PEEK and PEKK, known for their exceptional thermal resistance and mechanical strength, to low-temperature polyolefins like PP and PE, our technology enables us to process materials suited for diverse applications. We can provide tailored solutions to meet your specific requirements.

Looking to connect with an experienced team?

Look no further than Re:Build Oribi! We are excited to connect with you.